PCB Production And Assembly

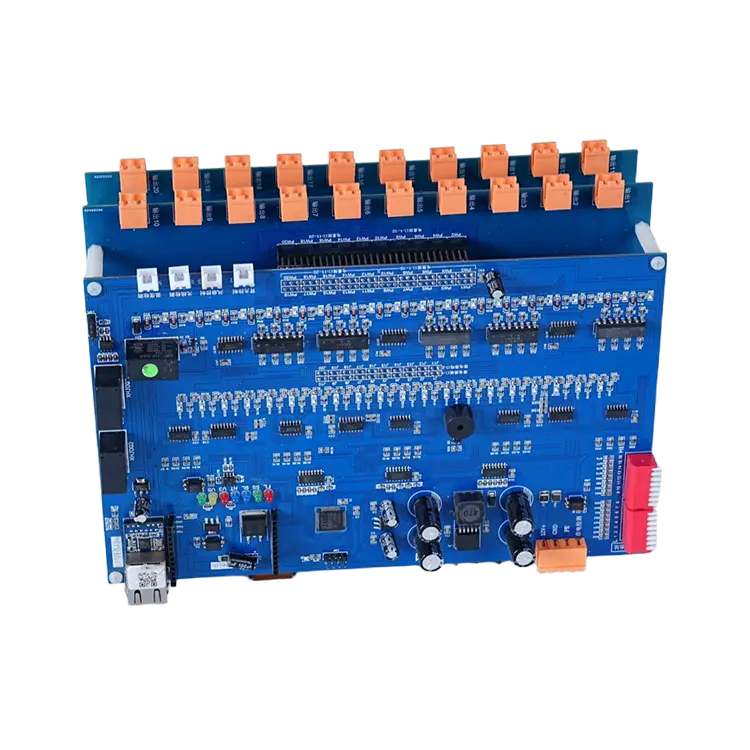

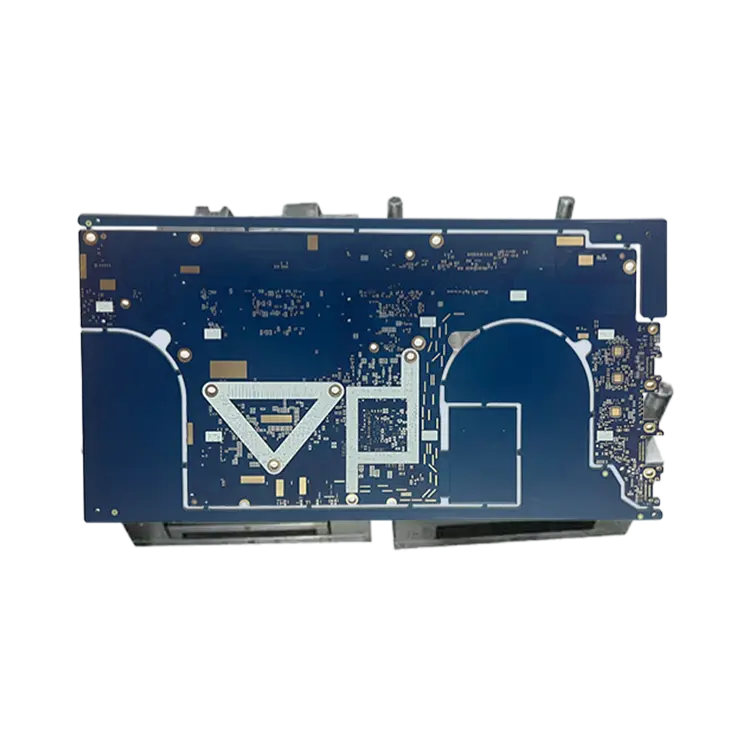

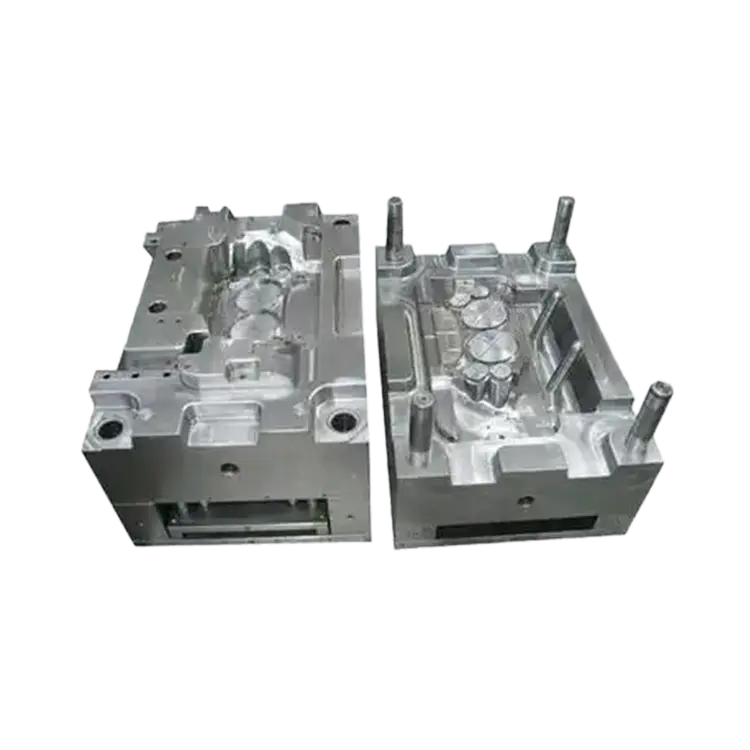

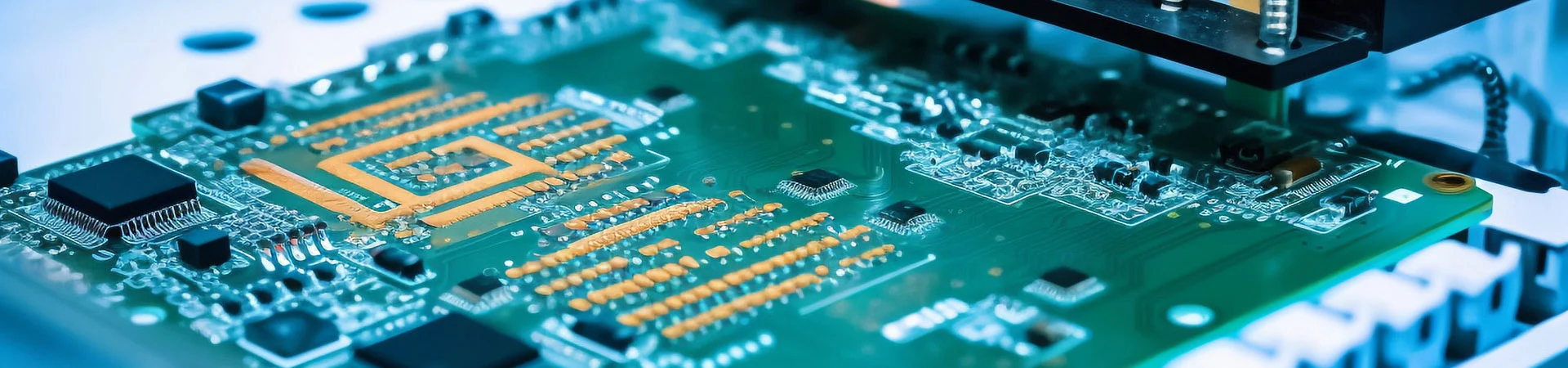

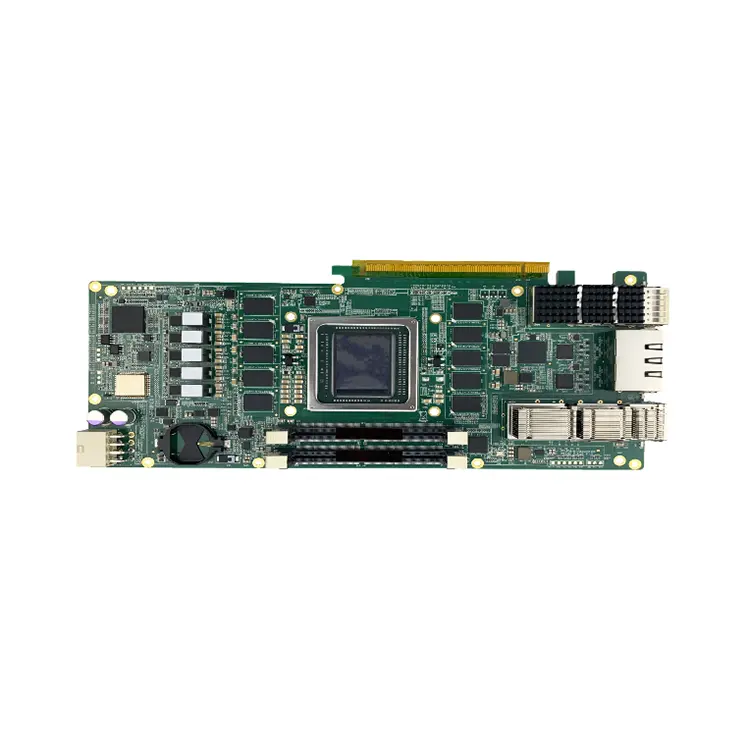

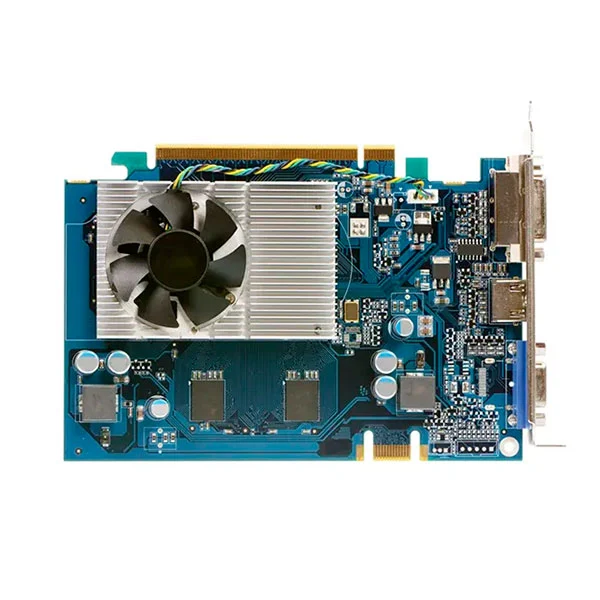

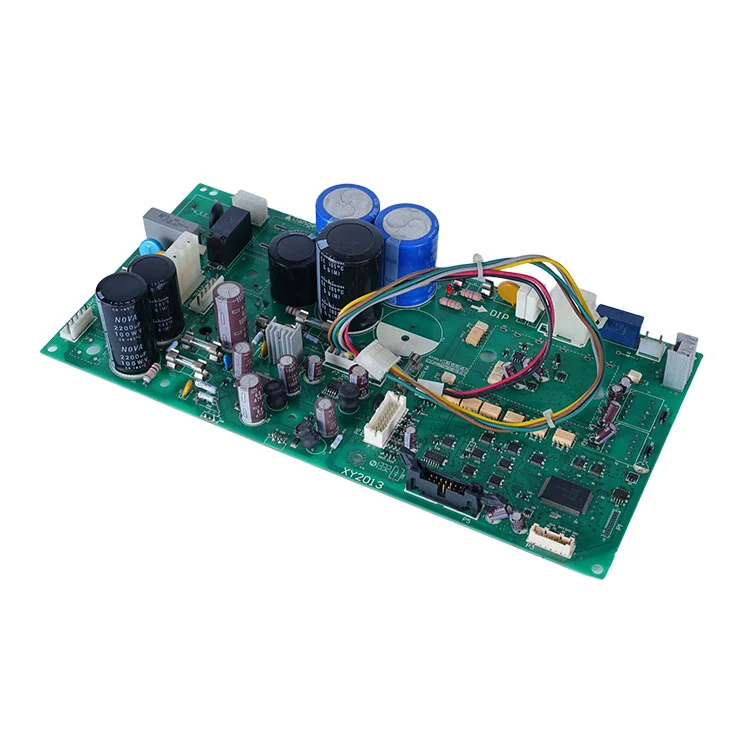

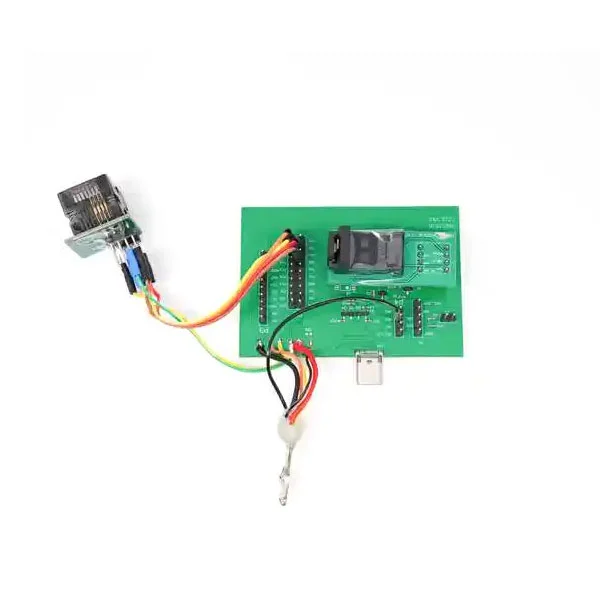

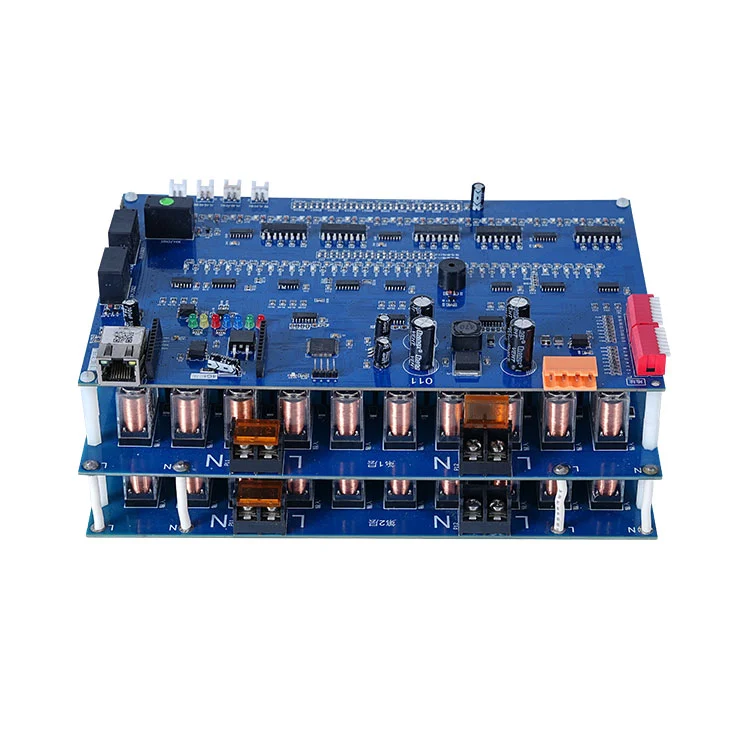

In today's fast-evolving electronics industry, reliable and precise PCB production is foundational to innovation. Our comprehensive services in PCB Assembly And Manufacturing cover every stage, from initial design to final testing. We specialize in PCB Fabrication Assembly, integrating advanced techniques to produce boards with exceptional accuracy and durability. For projects requiring modern component mounting, our Surface Mount PCB solutions offer high-density placements and improved performance. Additionally, our expertise in Electronic Circuit Board Assembly ensures seamless integration of all electronic components, adhering to strict industry standards and client specifications. Our team leverages state-of-the-art equipment and rigorous quality control to deliver PCBs that meet the demands of various applications, including consumer electronics, automotive systems, and industrial machinery. We prioritize efficiency, scalability, and cost-effectiveness, making us a trusted partner for both prototyping and large-scale production.

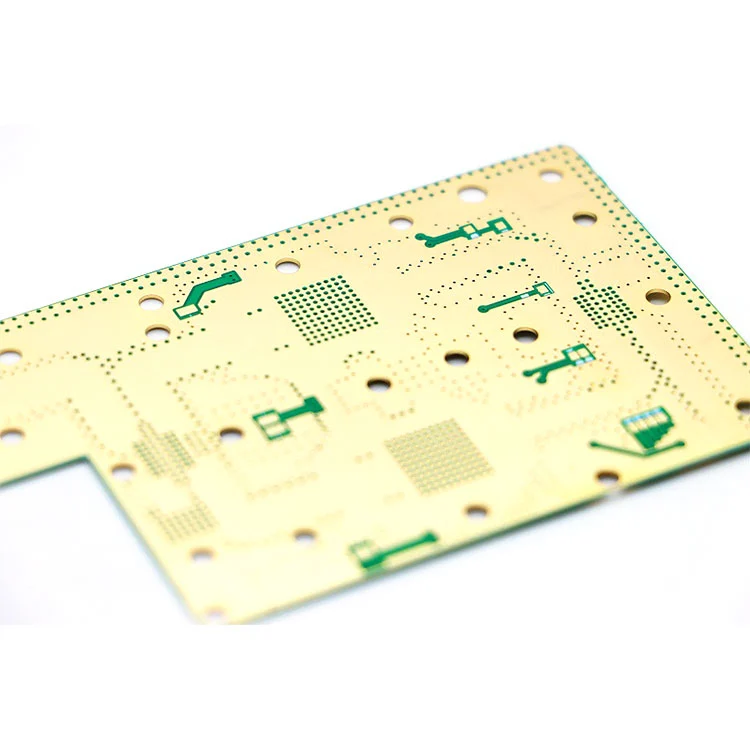

At the core of our offerings is <产品名字>, a versatile and high-performance solution designed to cater to diverse electronic needs. This product features a multi-layer construction with up to 24 layers, ensuring optimal signal integrity and thermal management. Key parameters include a minimum trace width of 3 mils and a dielectric constant ranging from 3.5 to 4.5, which supports high-frequency applications. The board material is FR-4 or Rogers, selected based on specific thermal and electrical requirements. <产品名字> also incorporates advanced surface finishes such as ENIG (Electroless Nickel Immersion Gold) and HASL (Hot Air Solder Leveling), enhancing solderability and corrosion resistance. Below is a detailed breakdown of its specifications:

- Layer Count: 1 to 24 layers

- Material: FR-4, Rogers, Aluminum

- Copper Weight: 0.5 oz to 6 oz

- Minimum Trace/Space: 3/3 mil

- Surface Finish: ENIG, HASL, OSP, Immersion Silver

- Dielectric Thickness: 0.1 mm to 3.2 mm

- Operating Temperature: -55°C to 150°C

For a quick comparison, refer to the table below:

| Parameter | Standard Range | Advanced Options |

|---|

| Board Thickness | 0.4 mm - 3.2 mm | Customizable up to 5 mm |

| Minimum Hole Size | 0.15 mm | 0.1 mm (laser drilling) |

| Impedance Control | ±10% tolerance | ±5% tolerance |

| Solder Mask | Green, Black, White | Multiple colors available |

| Silkscreen | White, Black | Custom legends |

These features make <产品名字> ideal for high-reliability applications, providing consistent performance and longevity. Our manufacturing process includes automated optical inspection (AOI) and electrical testing to guarantee each board meets the highest quality standards. Whether for simple circuits or complex multi-layer designs, <产品名字> delivers precision and reliability, backed by our decades of industry expertise.