PCB Assembly Services

As a professional manufacturer and global supplier deeply engaged in PCB assembly services, our goal goes far beyond simply providing basic services: for our employees, we serve as a platform for mutual growth; for our suppliers, we serve as a long-term, trusted collaborative partner; and for our buyers, we aspire to be a value co-creator through deep collaboration. This positioning has enabled us to gradually establish a virtuous ecosystem of "value sharing and market expansion" within the PCB assembly service sector.

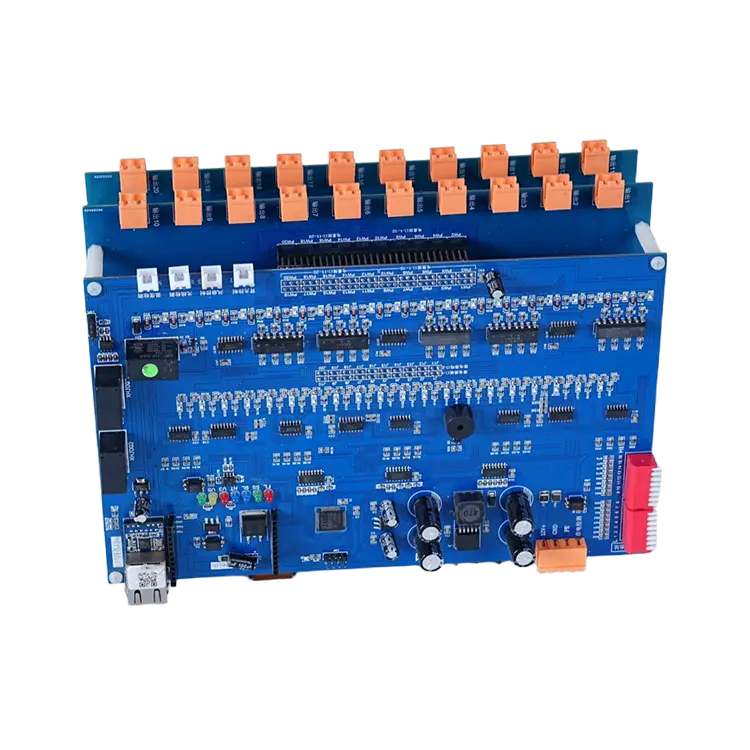

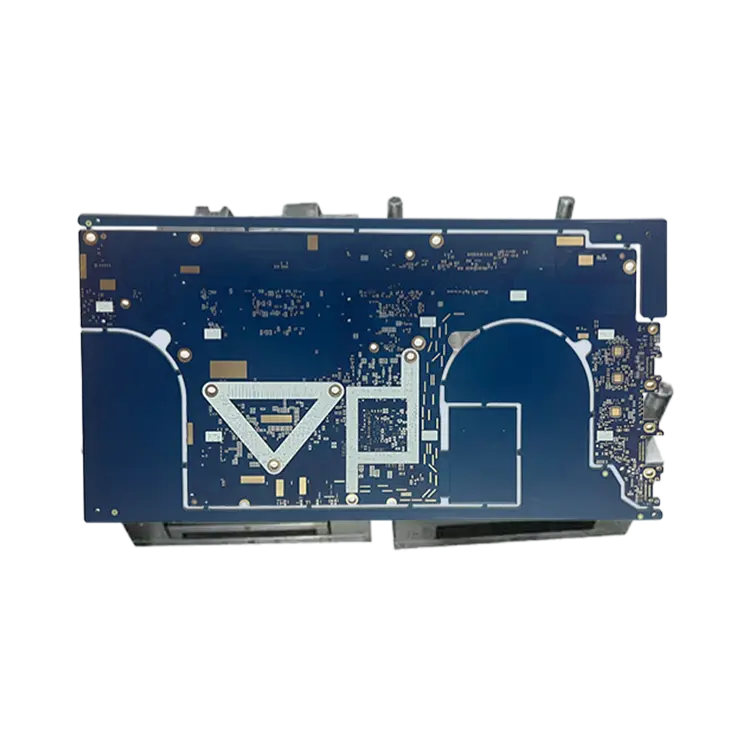

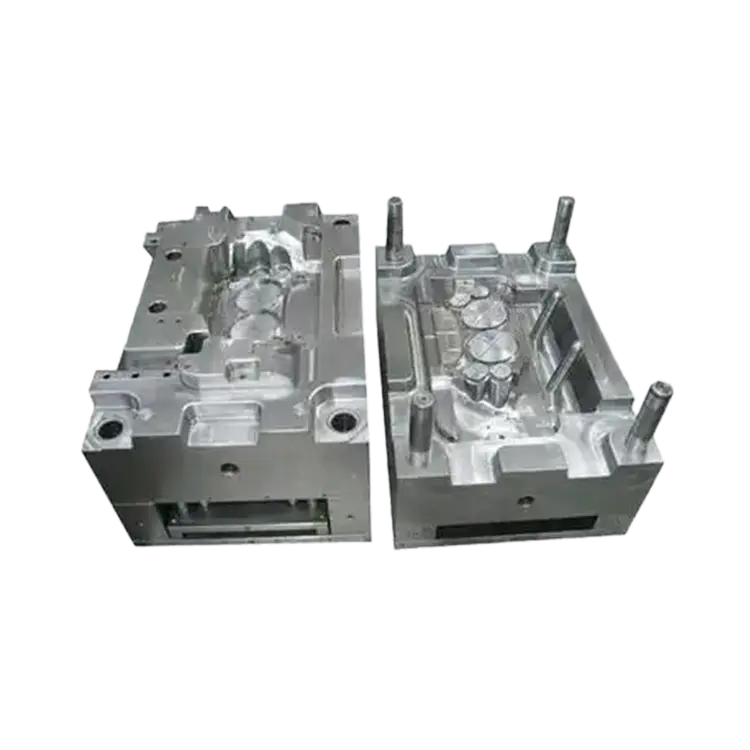

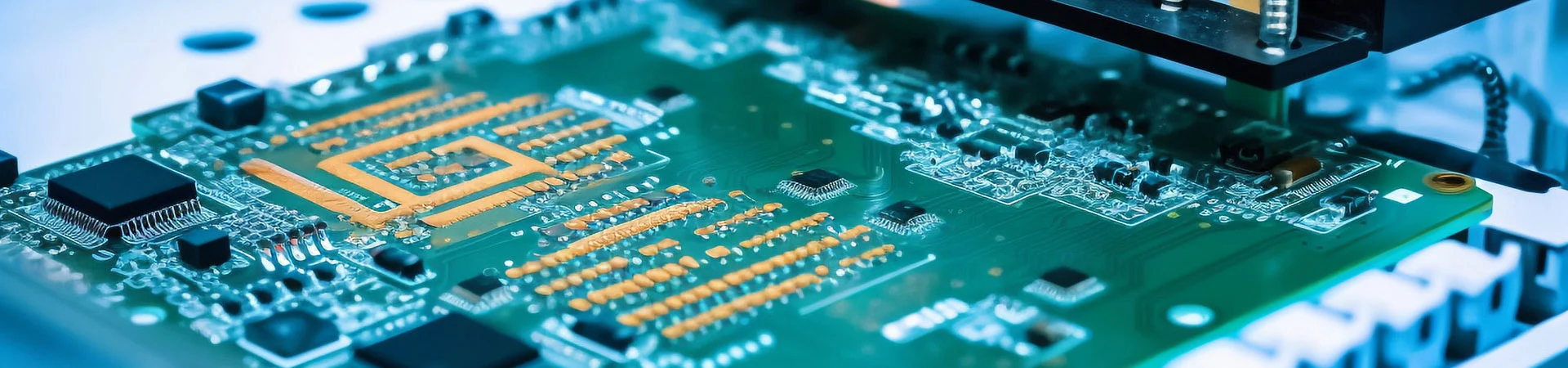

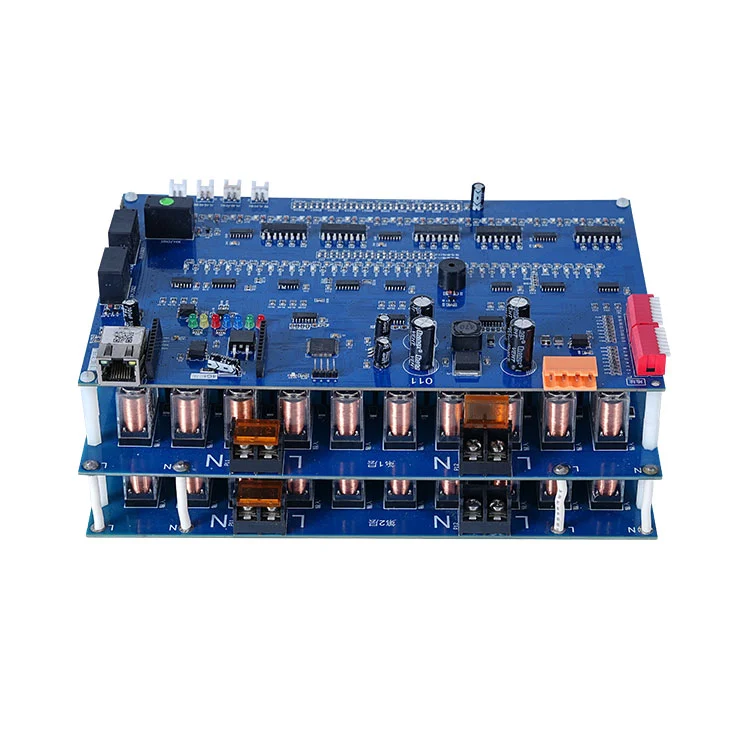

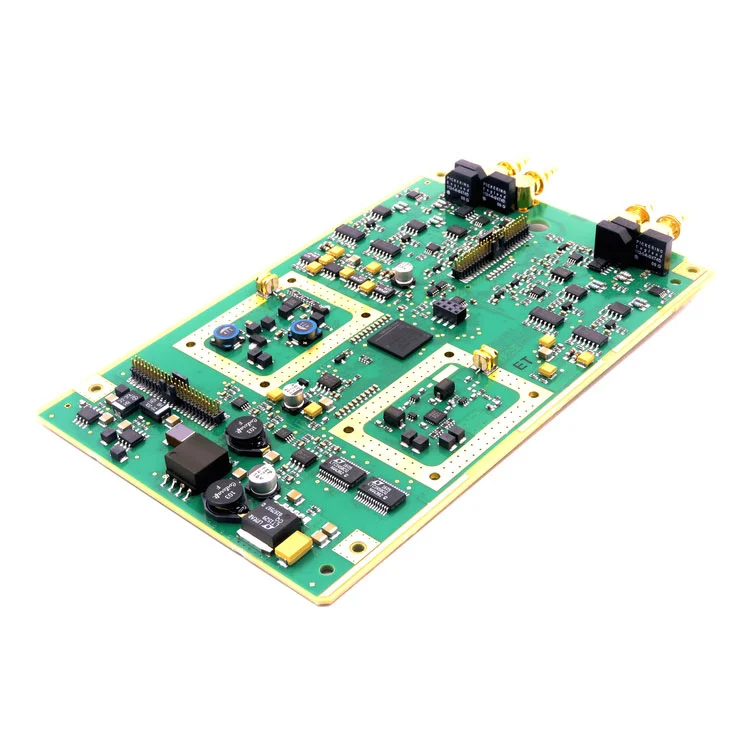

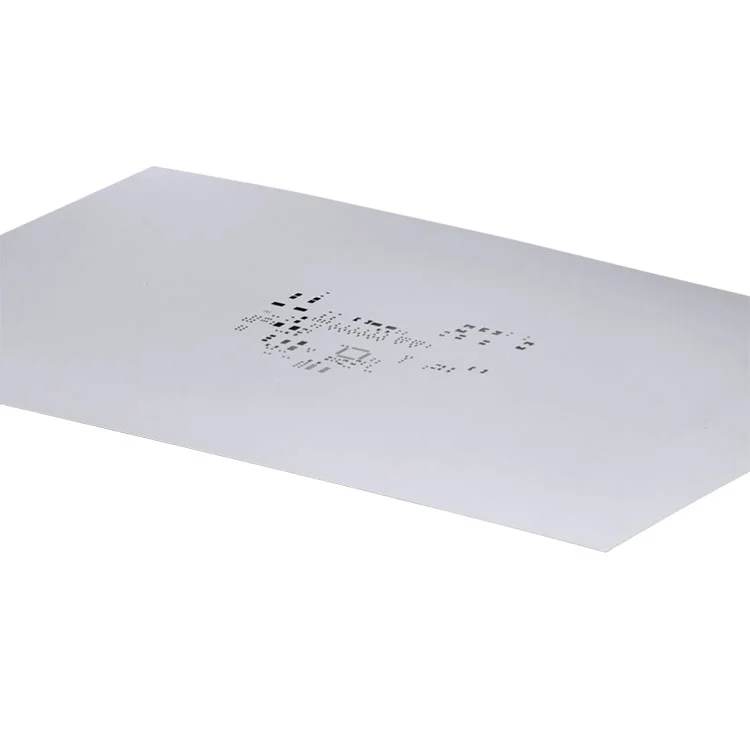

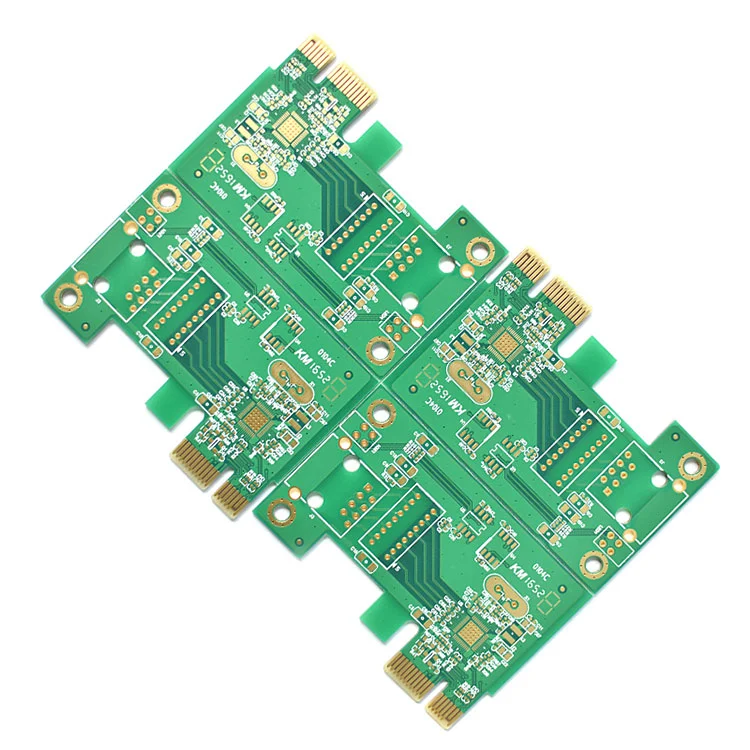

As a core manufacturer of PCB assembly services, Fanway's competitiveness lies in its professional control of the entire supply chain. From precise electronic component selection and high-speed SMT placement to PCBA functional testing and finished product packaging, we have established standardized operating procedures and traceability systems for every step. To expand into the international market, we have specifically optimized our "high performance + high cost-effective" service solutions to meet the diverse needs of overseas buyers, such as the high reliability of automotive electronics and the rapid iteration of consumer electronics. This not only ensures product compliance with international standards such as IPC-A-610, but also reduces overall manufacturing costs through process innovations (such as our proprietary placement path optimization system), helping customers enhance their market competitiveness. Over the years, Fanway has established stable partnerships with over 100 renowned companies, including leading domestic industrial control equipment manufacturers, Tier 1 European automotive electronics suppliers, and Southeast Asian consumer electronics brands. 80% of these customers have renewed their long-term supply agreements. This trust stems from our commitment to "delivering high quality at low cost." We do not simply reduce costs; rather, we transform these savings into profit margins for our customers through process improvements in R&D (for example, increasing the placement yield of 01005 components to 99.8%), intelligent upgrades in manufacturing (the introduction of an MES system in 2020 reduced production cycle time by 20%), and efficiency optimization in management (establishing a supplier collaboration platform to achieve a 99% material matching rate).

Customer recognition is the best honor. We obtained ISO 9001 quality management system certification in 2005 and IATF 16949 automotive quality system certification in 2008. These certificates not only endorse our production standards but also reinforce our corporate creed: "Quality is the foundation of survival, and reputation is the basis of development." From 100% spot checks upon incoming raw materials, to real-time monitoring by AOI equipment during assembly, to full-function testing before shipment, every step adheres to the principle of "leaving no problems to customers." A medical device client once urgently requested a batch of high-reliability PCBAs. We temporarily deployed our technical team to the factory, not only delivering the products three days ahead of schedule but also proactively identifying potential risks in the design. This exceptional service has earned us the client's "Best Strategic Supplier" award for three consecutive years.

We sincerely invite business colleagues from home and abroad to visit Fanway. From our fully automated SMT workshops to our visual quality control center, our intelligent warehousing system, and our collaborative R&D lab, every detail demonstrates our dedication to PCB assembly services. Whether it's a small or medium-volume sample run or a large-scale mass production order, as your trusted PCB assembly manufacturer and supplier, Fanway believes that true collaboration means working together to improve products and expand the market. We look forward to collaborating with more partners to build a long-term, mutually beneficial future in the PCB assembly industry.