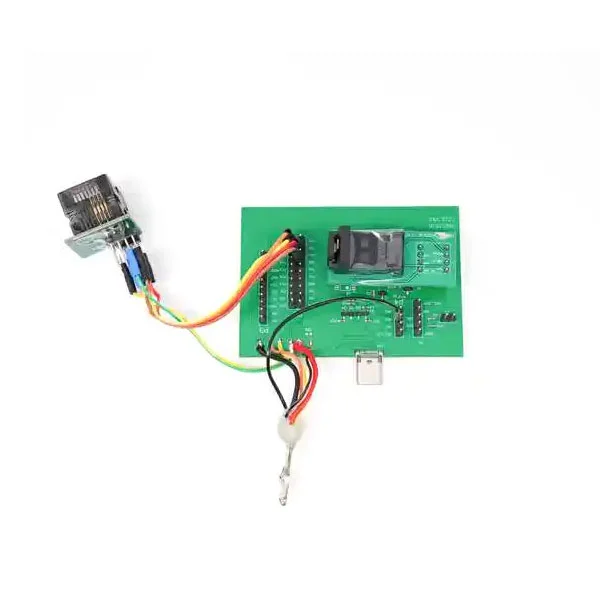

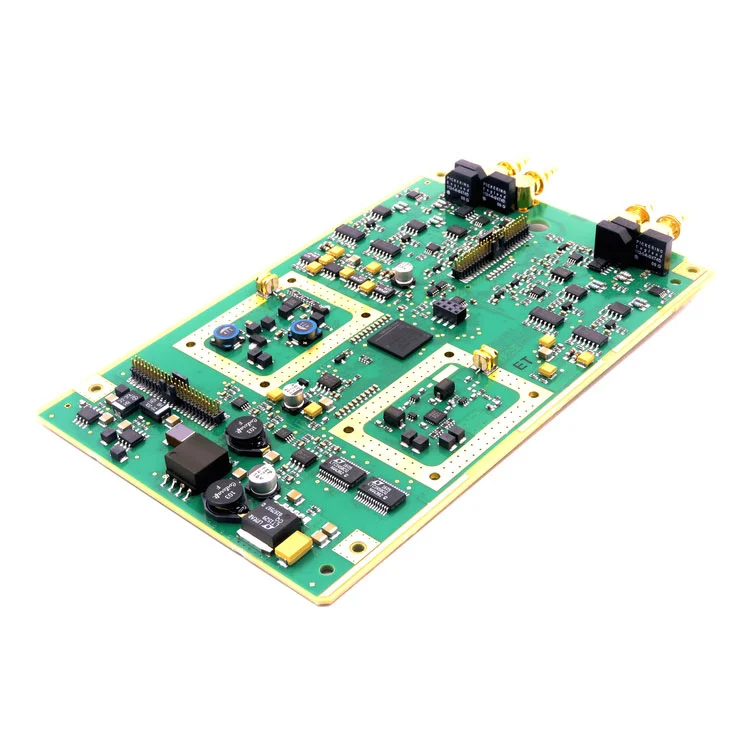

PCBA Manufacturing

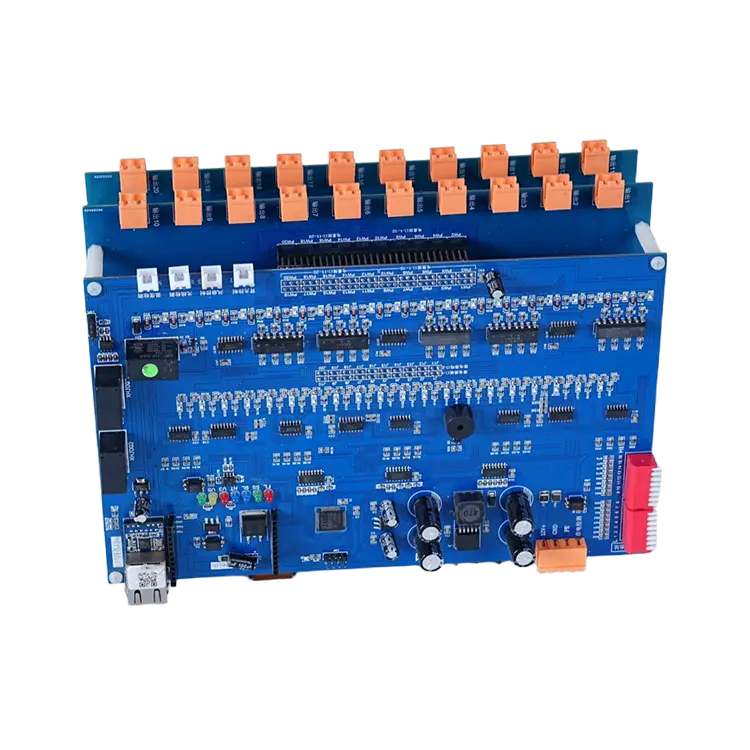

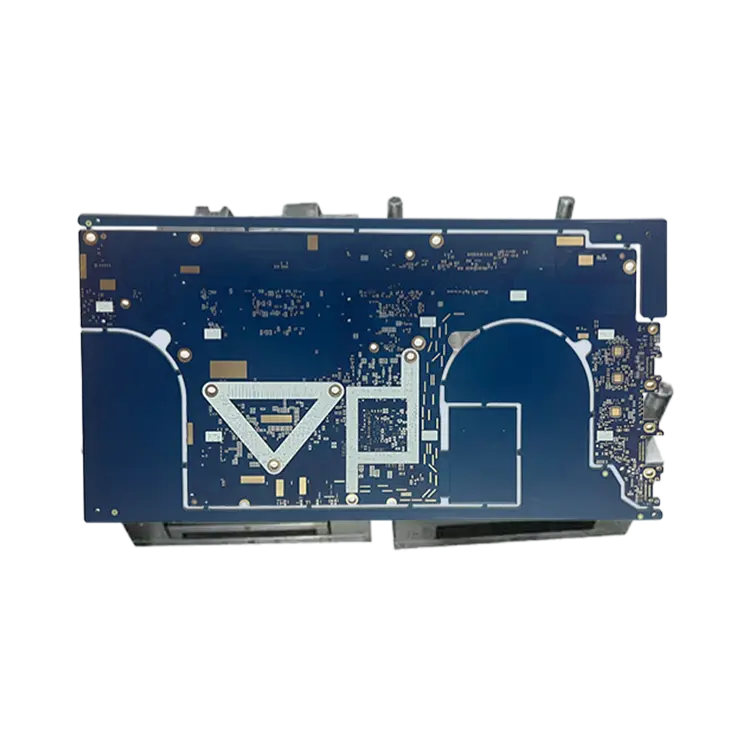

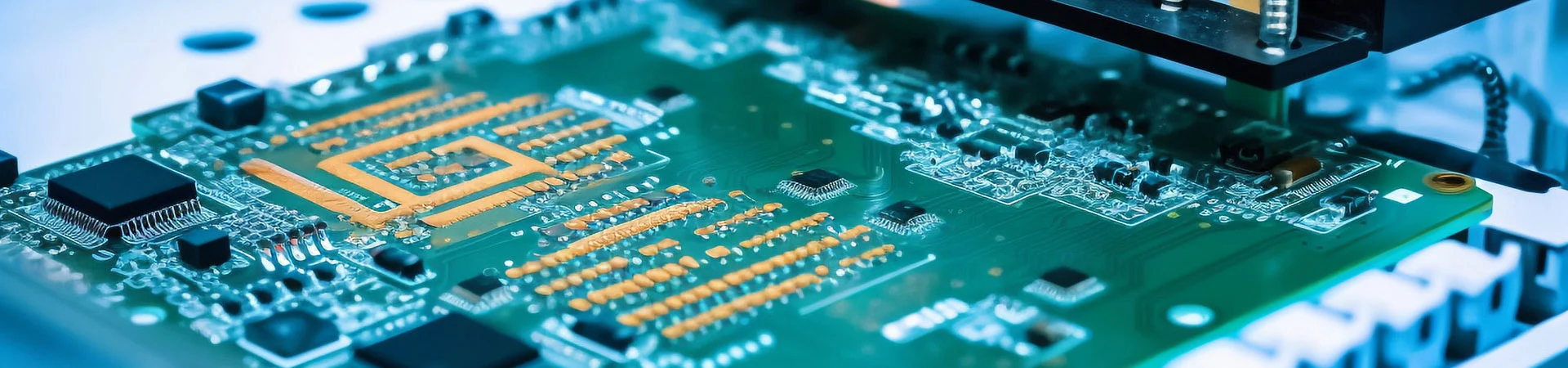

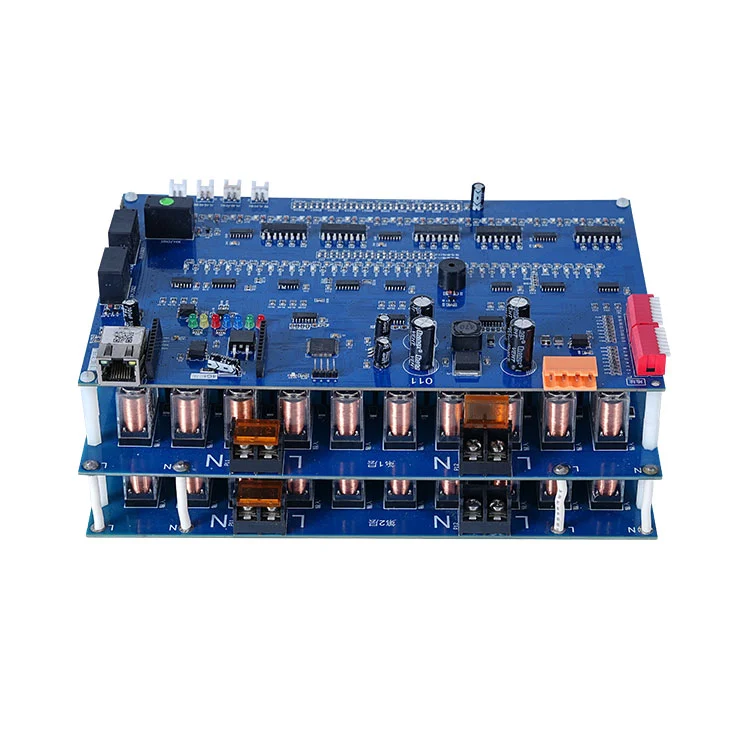

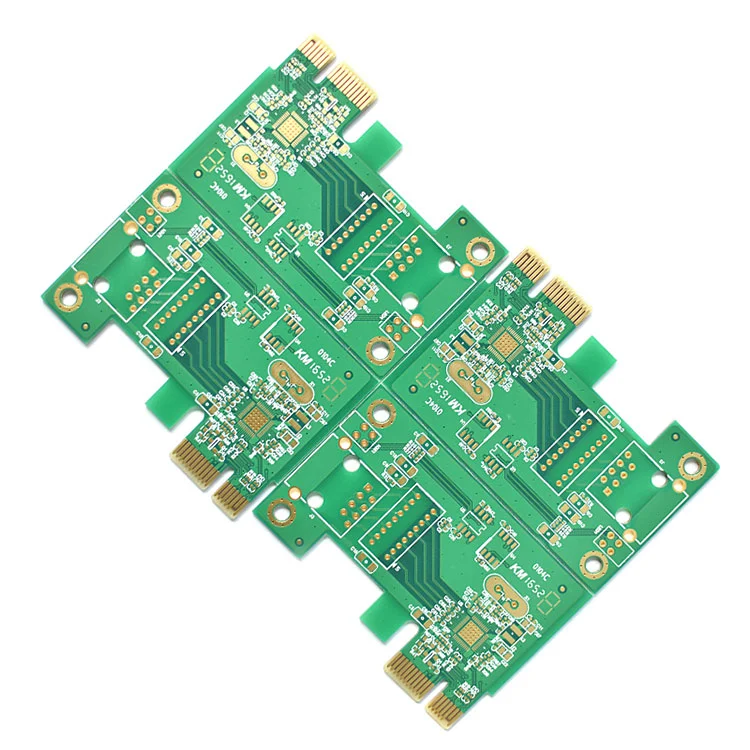

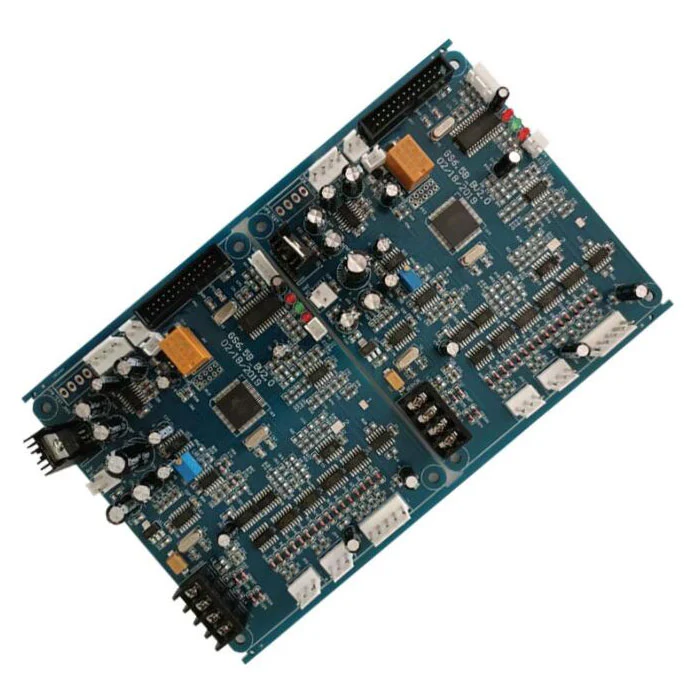

Fanway consistently adheres to the principle of "quality first, cost second" as its core competitiveness in PCBA manufacturing. Our production lines are equipped with imported Panasonic NPM-W2 placement machines (supporting 01005 component placement with ±0.01mm accuracy) and Koh Young SPI solder paste inspectors (3D measurement error ≤10μm) from the United States. Combined with a full-process traceability MES system (with over 200 production data points per circuit board), we ensure a stable product yield rate above 99.5%. Regarding cost control, we establish a VMI (vendor managed inventory) model with 20 core electronic component suppliers, and utilize our proprietary placement path optimization system (reducing material loss by 3%) to keep our overall product costs 8%-12% lower than the industry average. More importantly, we integrate "green manufacturing" into every process: using lead-free soldering processes (RoHS 2.0 compliant), promoting energy-saving equipment (production line energy consumption is 25% lower than traditional equipment), and establishing a scrap recycling system (metal recovery rate reaches 95%), truly providing customers with the dual value of "high quality + environmental protection."

Facing the wave of internet globalization and the internationalization of the electronics industry, Fanway is expanding into overseas markets with a more open attitude. We deeply understand that directly serving overseas customers not only shortens supply chain links and reduces intermediary costs, but also enables precise matching of needs through localized communication. To this end, we have established a professional overseas service team (with multilingual support including English, Spanish, and German), established a regional warehousing center in Southeast Asia (enabling 48-hour response time for emergency orders), and customized compliance solutions for different markets (such as CE certification support for European customers and UL testing assistance for North American customers). These initiatives have already yielded initial results: in 2023, Fanway's overseas PCBA manufacturing orders increased by 60% year-over-year. Its client base includes German industrial equipment manufacturers, US medical electronics brands, and Brazilian consumer electronics companies, with 70% of new customers being referred by established clients.

Whether serving long-standing domestic partners or first-time overseas buyers, Fanway remains committed to being a "reliable PCBA manufacturing supplier": We provide more than just a circuit board assembly; we offer comprehensive support, from understanding requirements to delivery and after-sales service. If you have PCBA manufacturing needs, please feel free to contact us. Simply provide specific technical specifications (such as number of layers, component specifications, environmental testing requirements) and delivery timelines, and we will provide a customized quote within 24 hours, including cost analysis, process solutions, and environmental certifications.