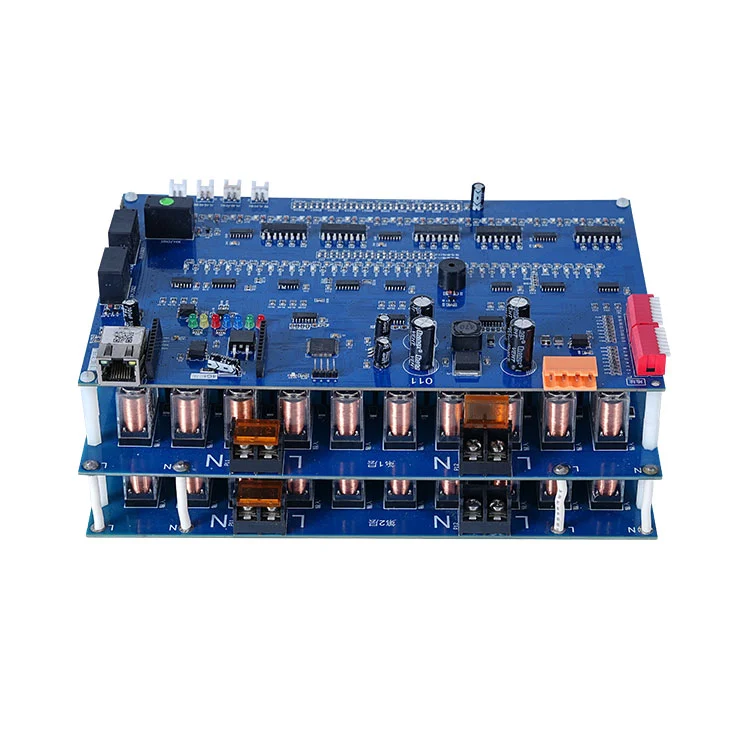

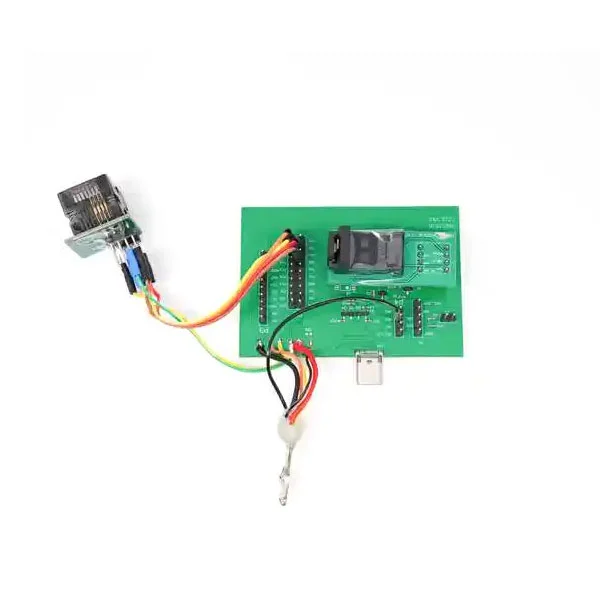

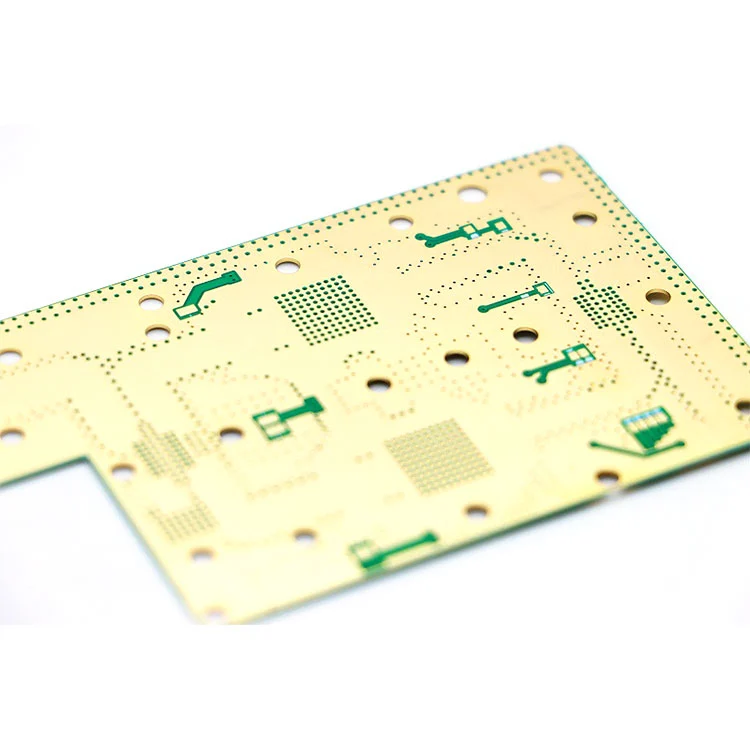

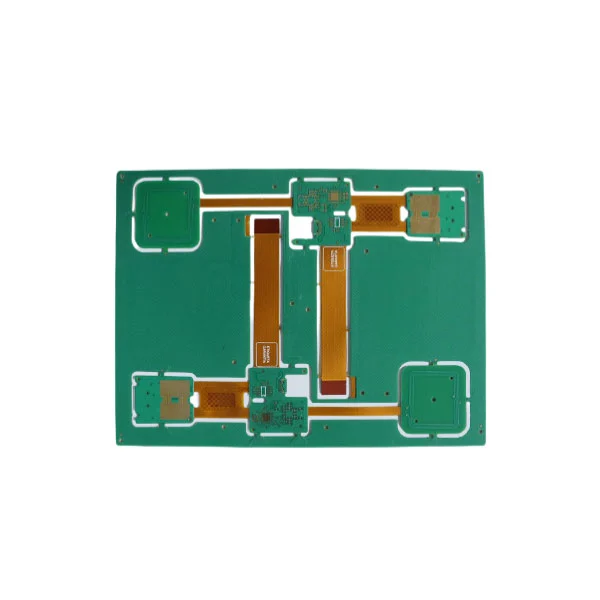

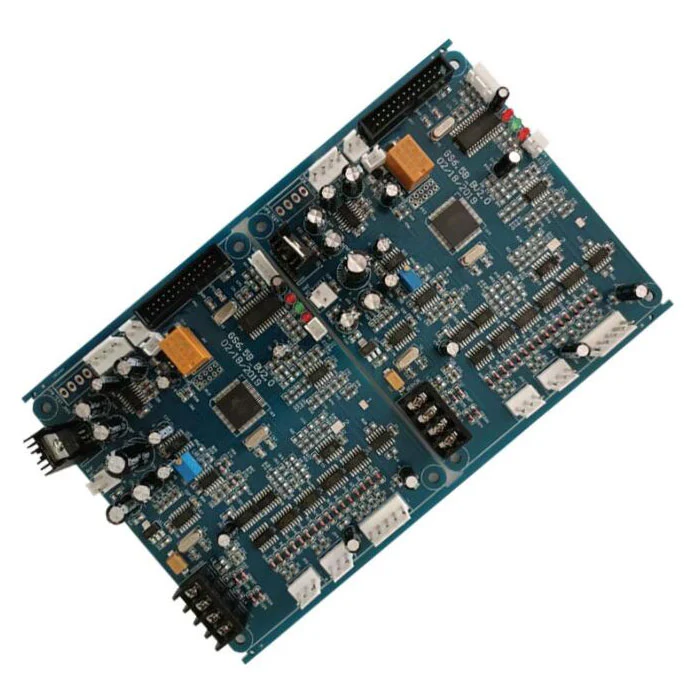

PCB Manufacturing and Assembly

When it comes to quality control, Fanway uses certifications as a mirror to illuminate the essence of our manufacturing. We achieved ISO 9001:2015 quality management system certification in 2018 and EU CE certification (covering the Low Voltage Directive and the Electromagnetic Compatibility Directive) in 2020. These authoritative recognitions not only validate the entire PCB Manufacturing Assembly process but also provide customers with tangible assurance: from SGS third-party testing of incoming raw materials, to full MES traceability of every PCB during production, to 100% functional testing before shipment, every step strictly adheres to certification standards. During an on-site audit, a German industrial equipment customer highly praised our first-article inspection records (over 2,000 pieces of process data are stored for each batch) and our defective product handling process (root cause analysis is initiated within 2 hours), stating, "With such management, product quality is naturally reassuring."

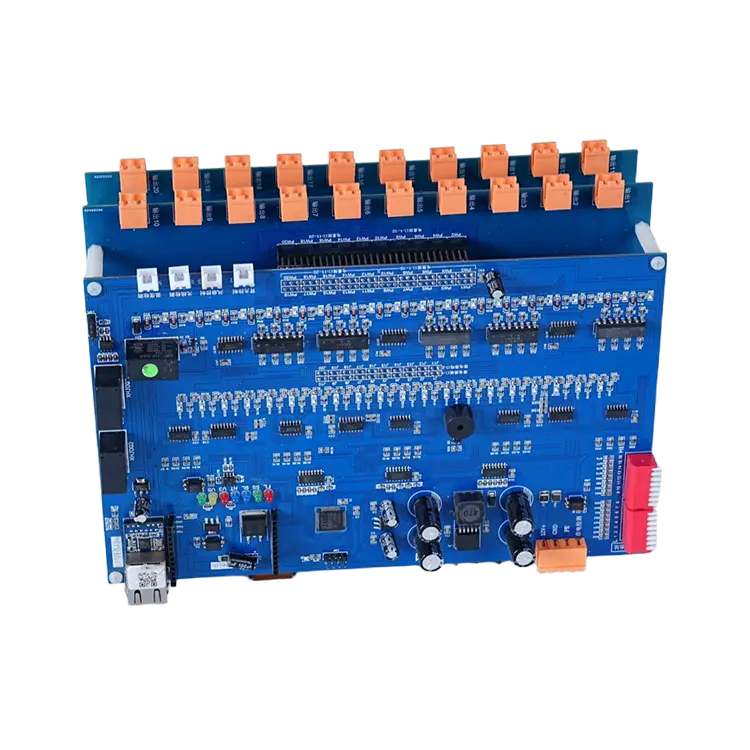

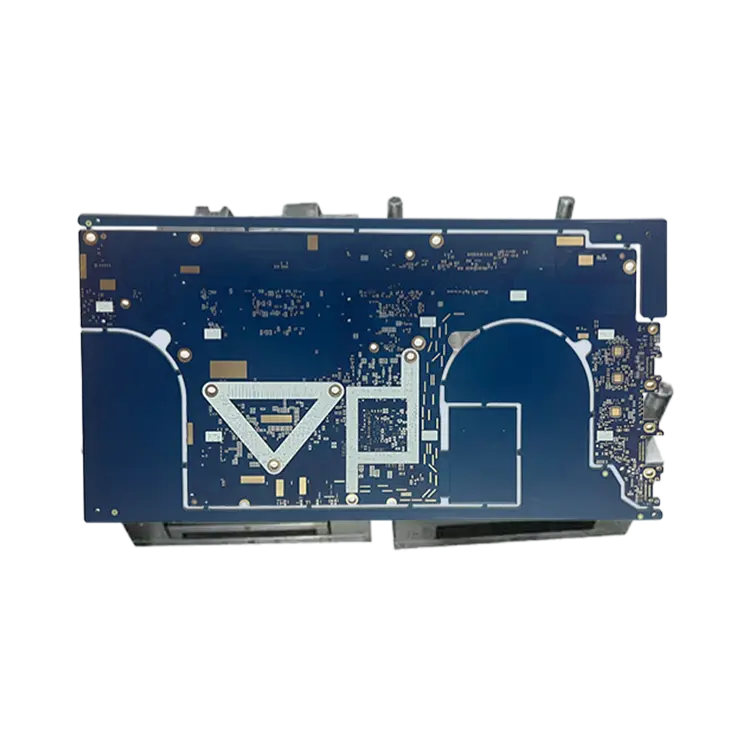

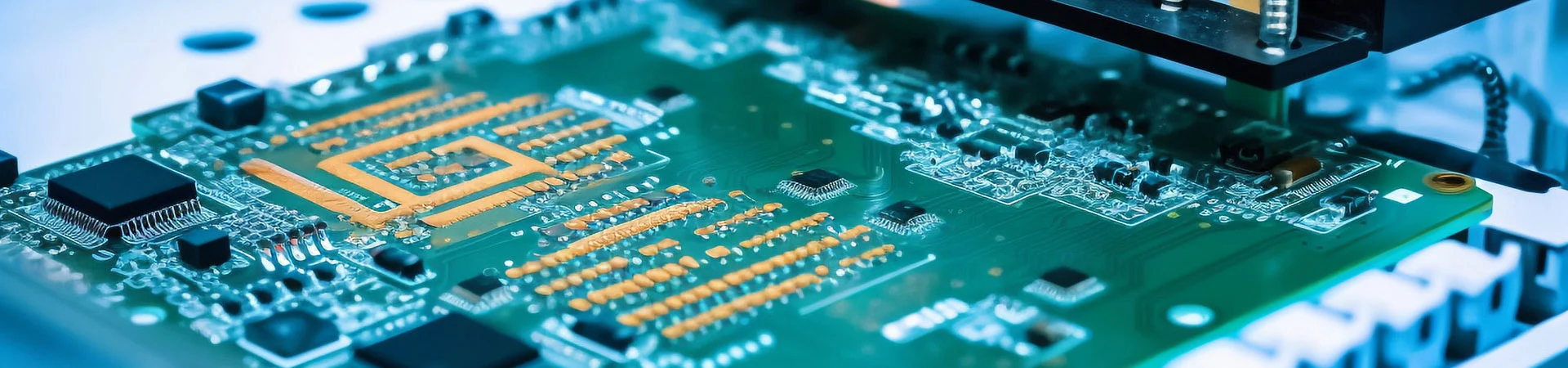

As a reliable supplier in the PCB Manufacturing Assembly field, Fanway's products consistently adhere to the quality principle of "national standards as the foundation, customer-centric." Our circuit board assemblies not only comply with mandatory domestic standards such as GB/T 4588.3 (Printed Circuit Board Design) and GB/T 2423 (Environmental Testing), but can also adapt to international specifications such as IPC-A-610 Class II/III (Electronic Assembly Acceptance) and J-STD-001 (Soldering Standards) based on customer needs. In terms of cost control, we optimize material procurement collaboration (establishing a VMI consignment model with 20 core electronic component suppliers) and upgrade production processes (introducing laser cutting technology to increase multilayer board processing efficiency by 30%). This reduces overall product costs by 8%-10% compared to the industry average, truly achieving "high quality at an affordable price"—which is why our PCB Manufacturing Assembly products have secured long-term orders from both domestic new energy vehicle companies and Southeast Asian consumer electronics brands. We sincerely invite global sourcing partners to visit Fanway. From our modern SMT workshop (equipped with Siemens Siplace SX placement machines, supporting high-speed placement of 01005 components) to our visual quality control center (real-time monitoring of 128 key quality control points), our collaborative R&D lab (providing Design for Manufacturability (DFM) analysis services), and our intelligent warehouse (AGVs ensure precise material delivery within 30 minutes), every aspect showcases our expertise and dedication to PCB Manufacturing Assembly. Whether you require small-batch sample verification or large-scale production support, as your trusted manufacturer and supplier, Fanway upholds the "One-time partnership, lifelong partnership" philosophy, providing one-on-one service from demand matching and solution customization to delivery and after-sales service.

If you are interested in Fanway's PCB Manufacturing Assembly products, please feel free to contact us. Simply provide your specific technical specifications and delivery requirements, and we will provide you with a customized quote within 24 hours. We look forward to meeting with you face-to-face to embark on a long-term, mutually beneficial partnership.