Printed Board Assembly

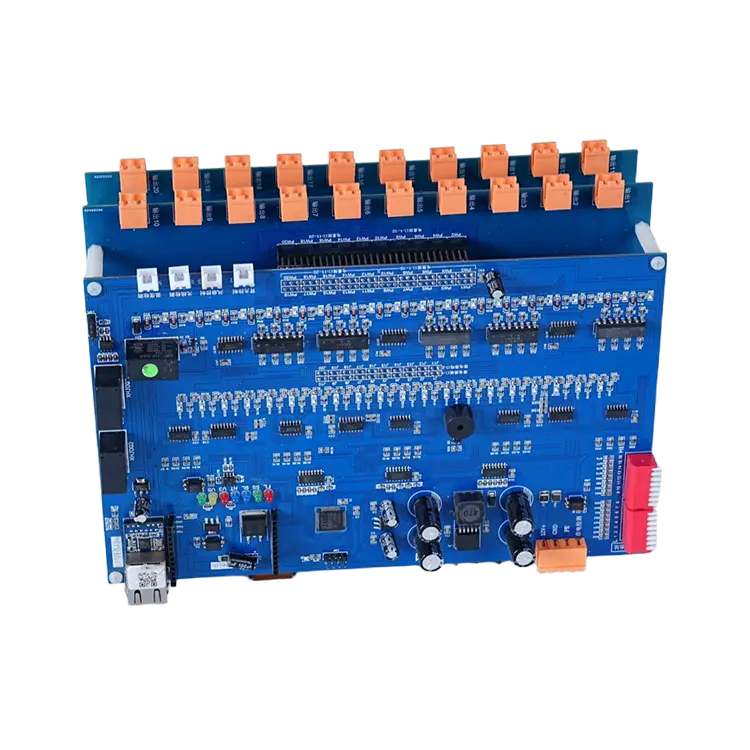

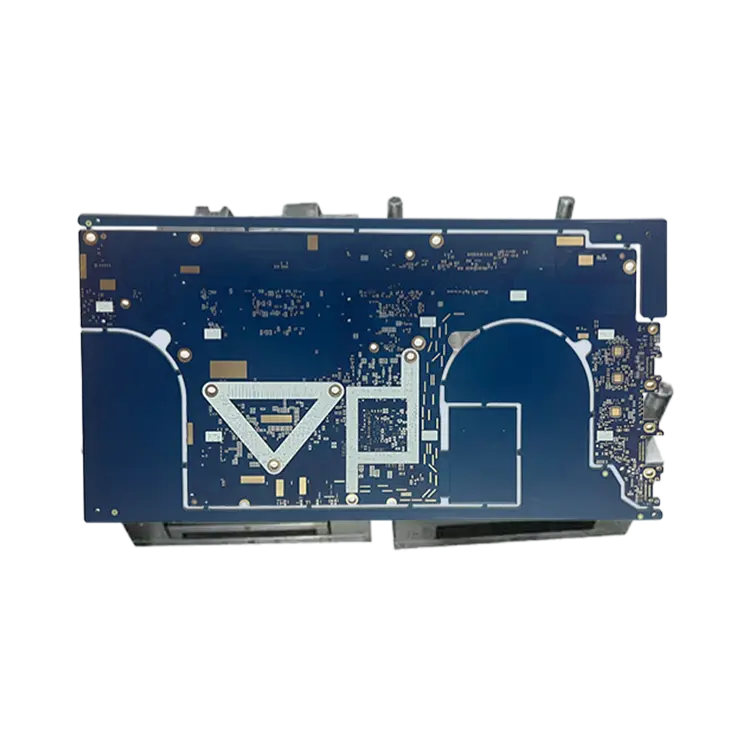

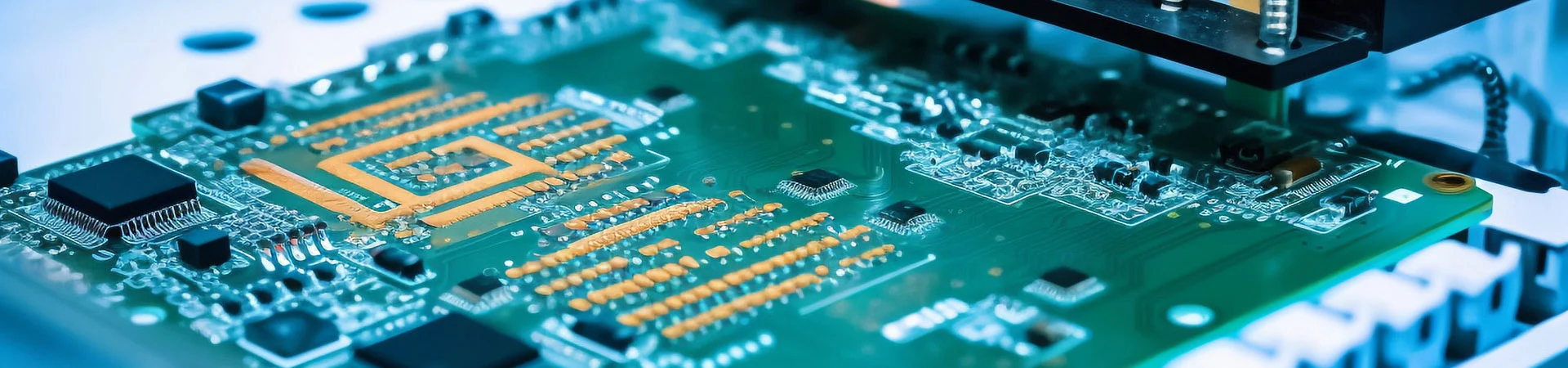

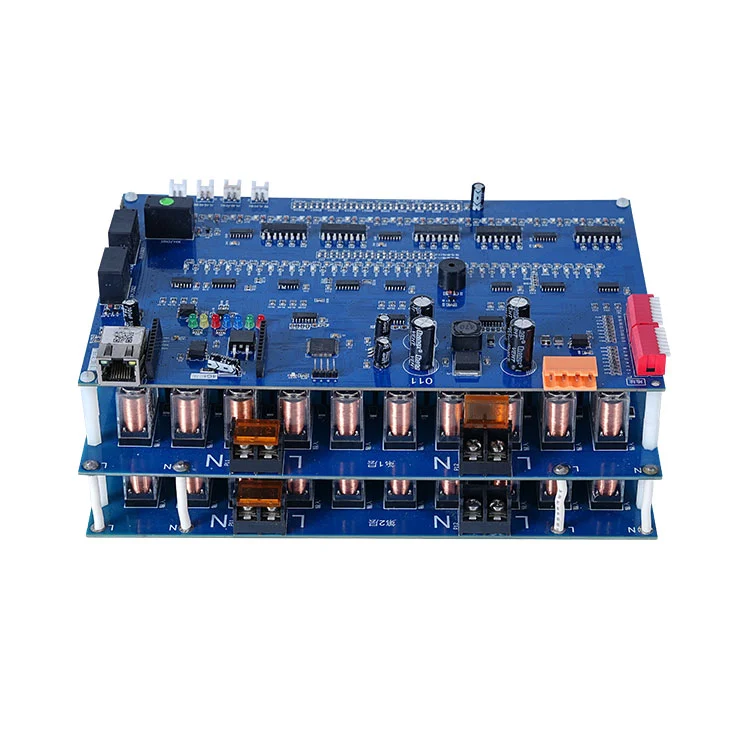

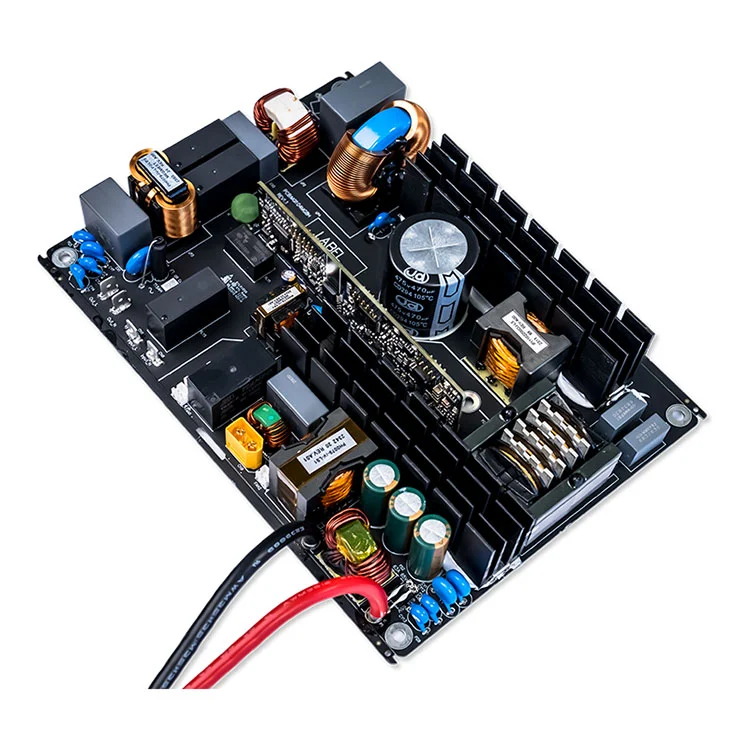

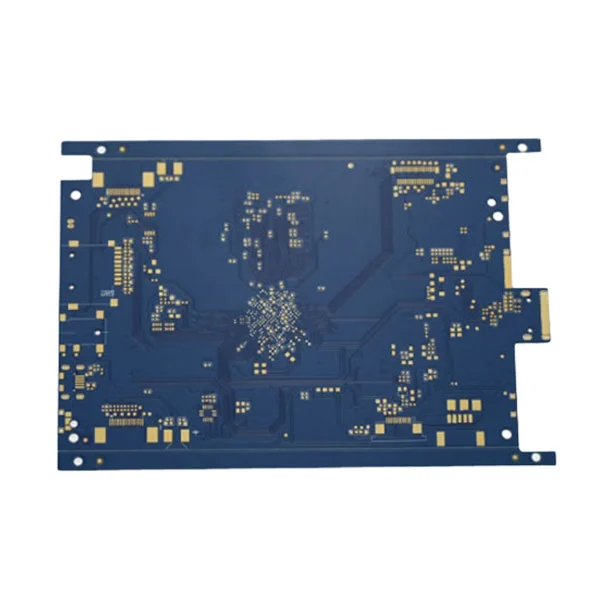

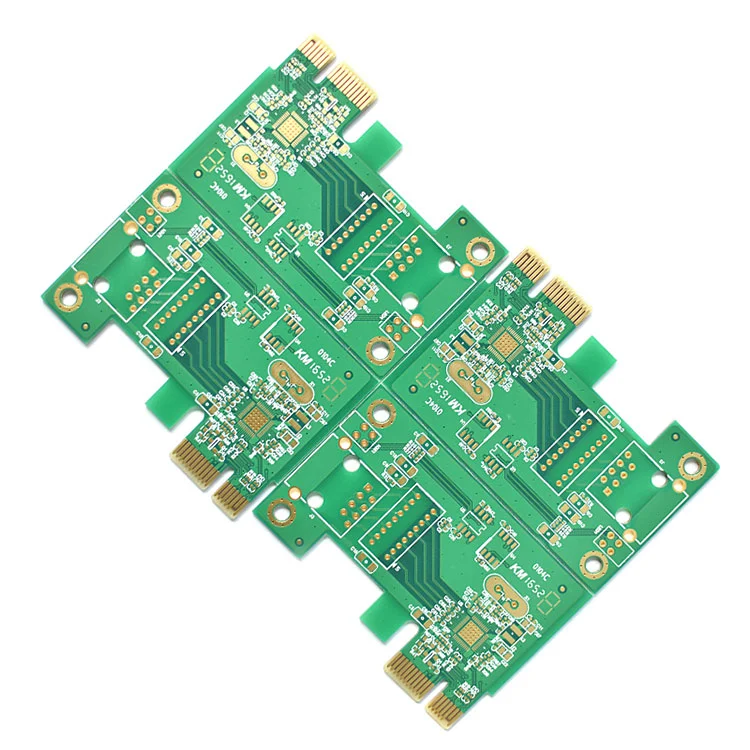

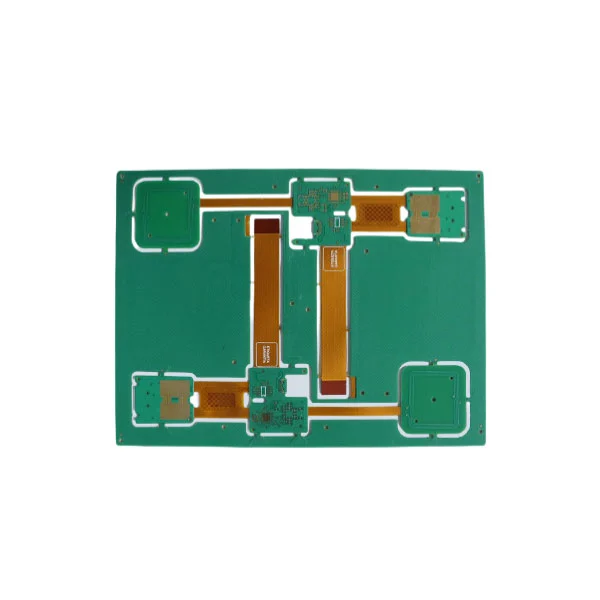

Quality is Fanway's lifeline. This isn't just a slogan; it's a principle ingrained into our production processes. We've established a three-stage quality control system: at the incoming material stage, all electronic components undergo XRF (X-ray fluorescence spectroscopy) testing (to ensure the absence of harmful substances) and solderability testing; during production, each circuit board undergoes a triple screening process: SPI (solder paste thickness measurement), AOI (automated optical inspection), and X-ray (internal solder joint inspection); and at the shipping stage, 100% functional testing (simulating actual customer usage environments) is performed. This stringent standard ensures a consistent yield rate of over 99.6% for our Printed Board Assembly products. We have also received international certifications such as ISO 9001:2015 (quality management), IATF 16949:2016 (automotive), and UL (US safety). These certificates serve not only as a testament to our credentials but also as a "quality guarantee" for customers choosing Fanway.

Customer needs are Fanway's guiding principle. Our sales team is comprised of professionals with an average of over eight years of industry experience. They are not only familiar with printed board assembly technical specifications (such as layer count, line width and spacing, and surface treatment processes), but also have a deep understanding of customers' real-world application scenarios (such as the temperature resistance requirements of industrial equipment and the trend towards thinner and lighter consumer electronics). We currently have five regional service centers in the Yangtze River Delta, Pearl River Delta, and Southeast Asia, each staffed with technical support engineers to ensure a 48-hour response time. This "localized + specialized" service model has enabled us to establish long-term partnerships with over 150 clients, including leading domestic industrial control companies, European medical device manufacturers, and North American communications equipment brands. 75% of these clients have been partners for over three years.

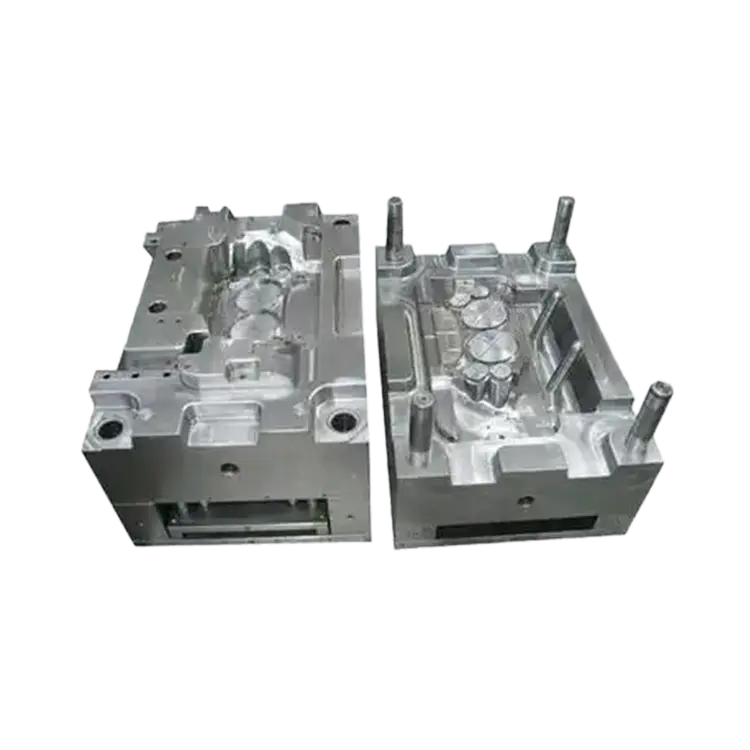

For our supplier partners, Fanway consistently adheres to the principle of "short-term win-win, long-term symbiosis." We have established a strict supplier access mechanism (requiring ISO 9001 certification and third-party test reports for key materials). We also use a VMI (vendor-managed inventory) model to reduce inventory pressure and enhance the added value of their products through technological collaboration (such as the joint development of new resistors and capacitors). A core electronic component supplier once reported: "After cooperating with Fanway, the proportion of our customized products increased from 30% to 60%, and our gross profit margin increased by 12%." This two-way empowerment has enabled us to maintain a supplier stability rate of over 95%, forming a healthy ecosystem for the Printed Board Assembly industry chain.