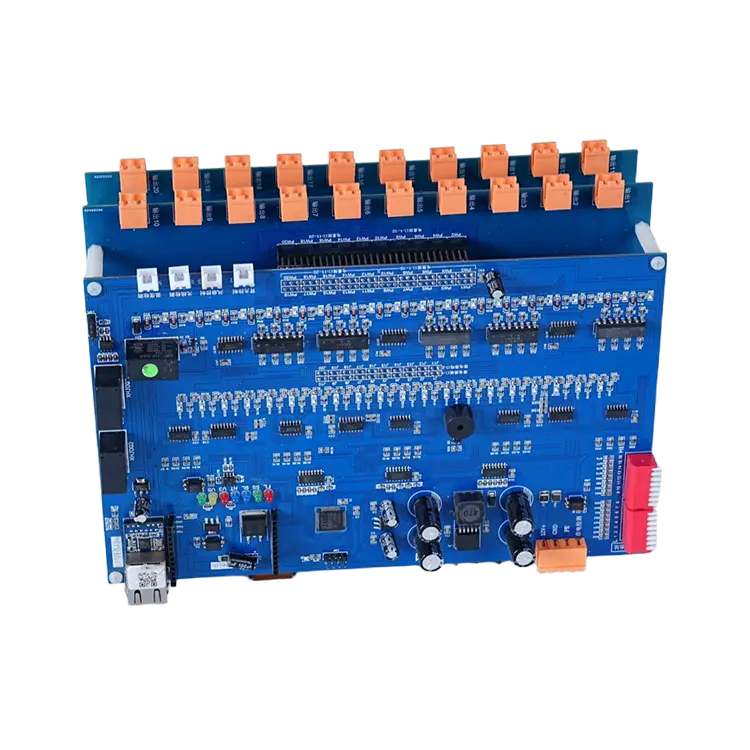

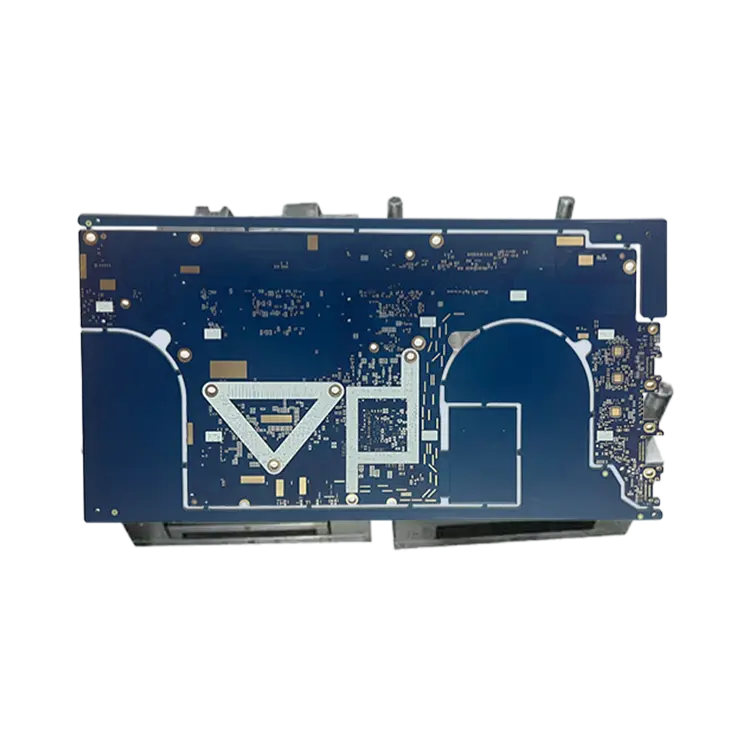

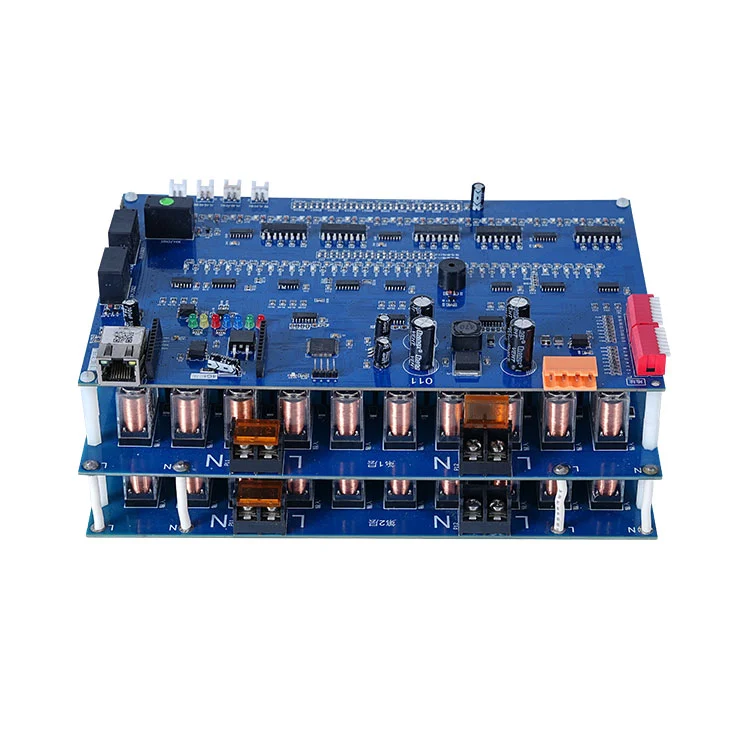

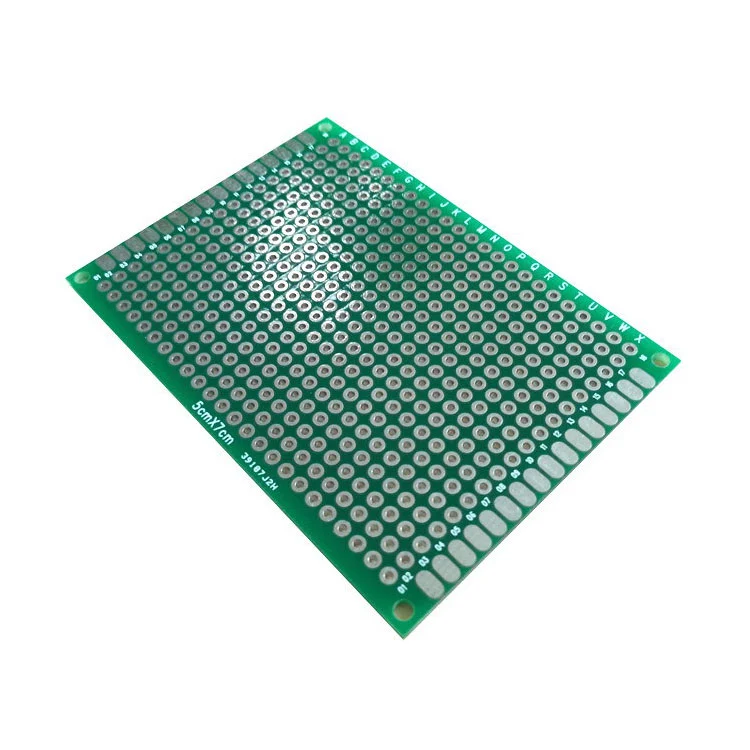

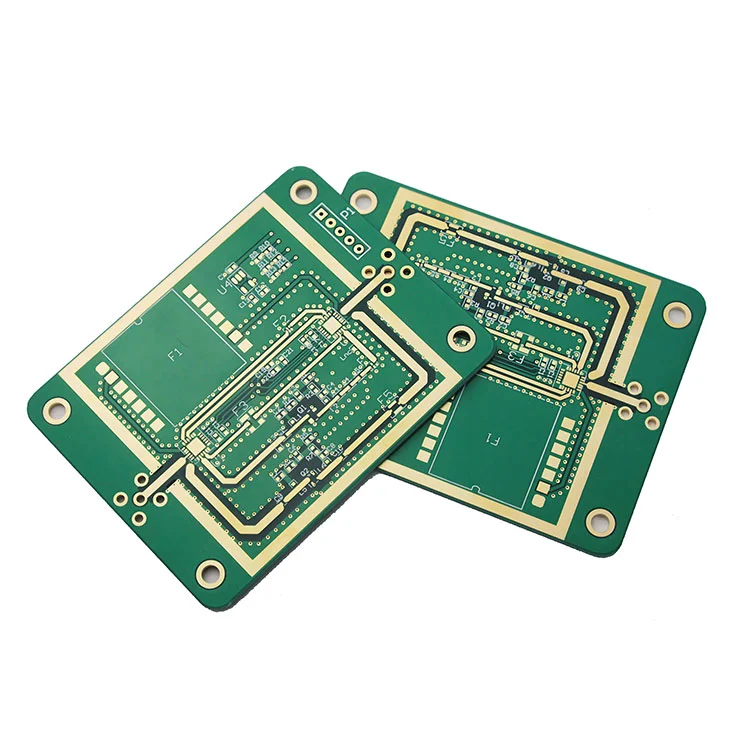

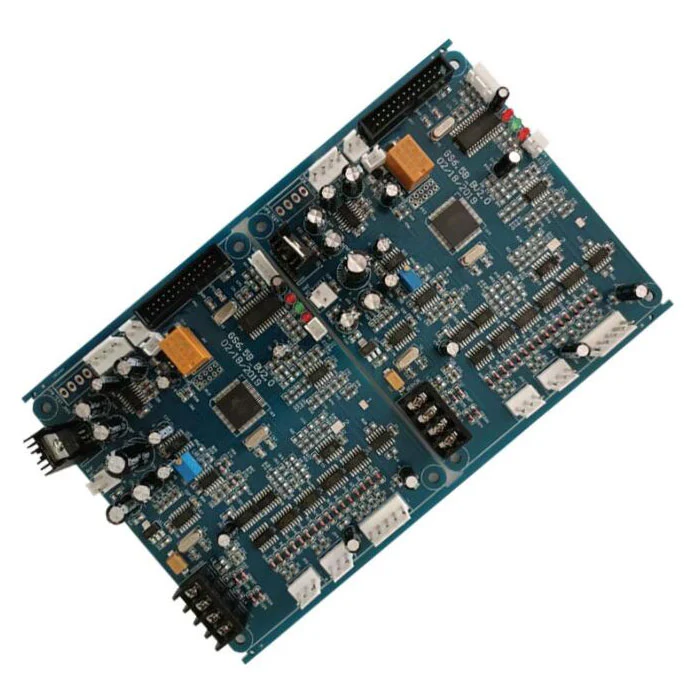

PCB Board Assembly

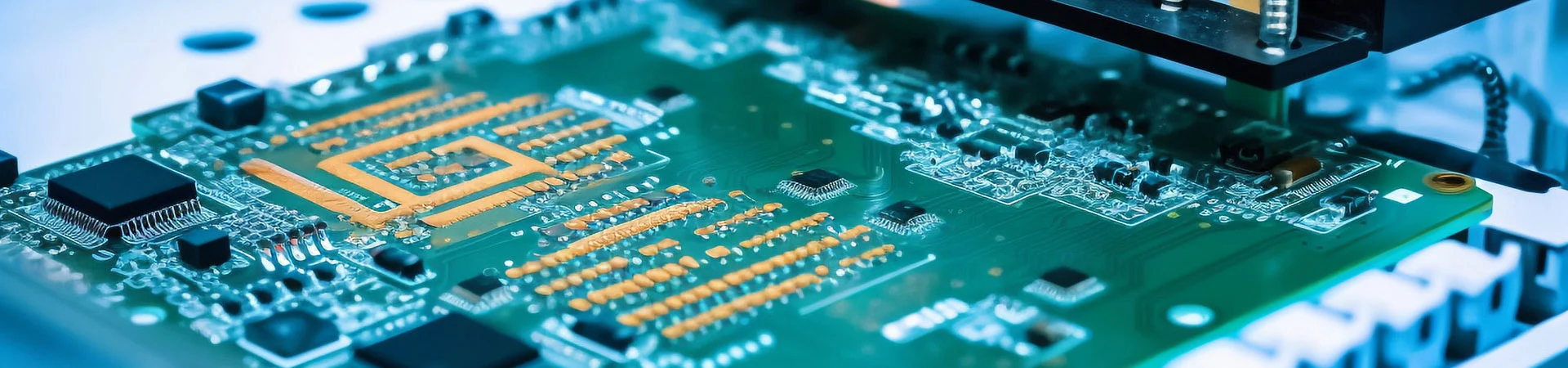

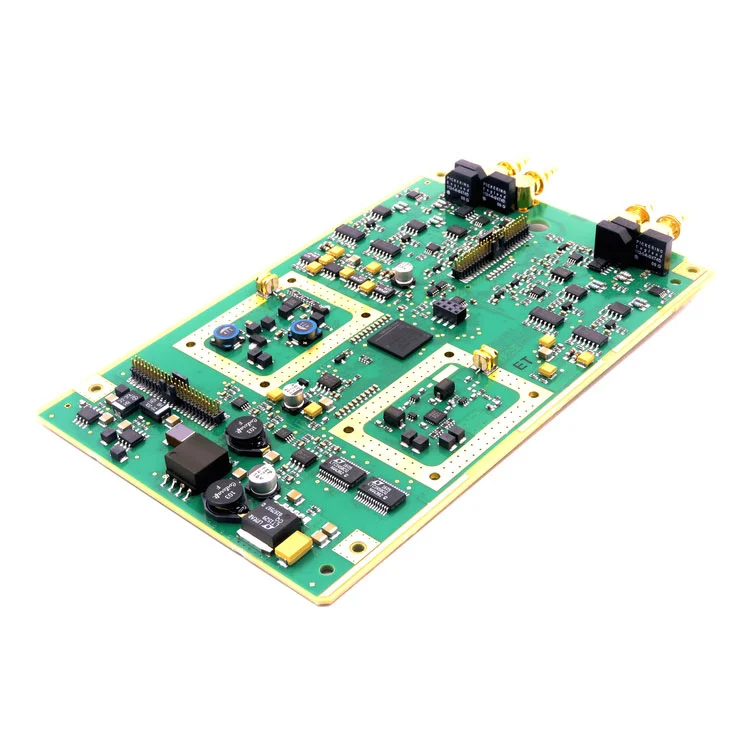

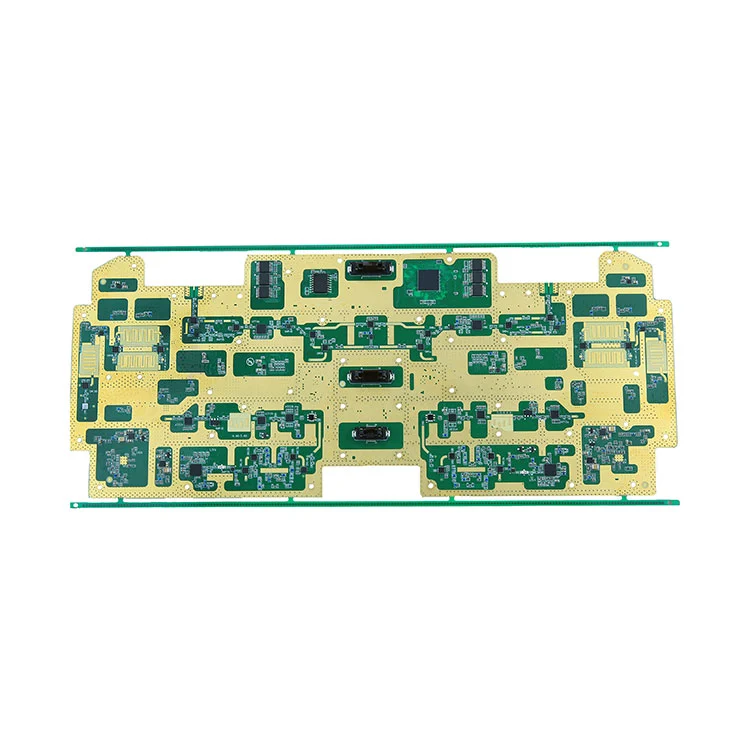

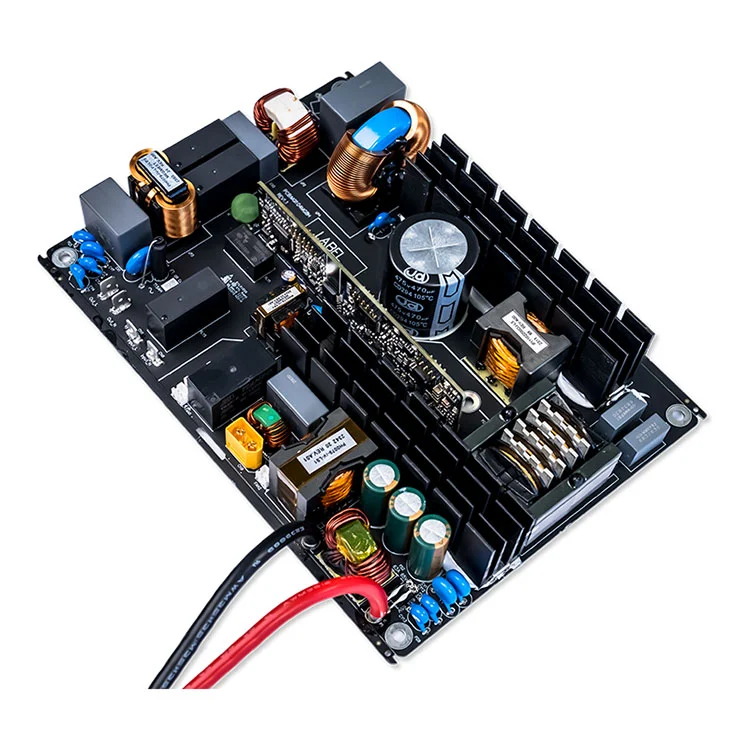

In the field of PCB board assembly, Fanway's dedication to detail is evident. Our SMT production lines, equipped with German-imported DEK printers and Siemens high-speed placement machines, achieve ±0.01mm placement accuracy for 01005 micro-components. Our AOI automated optical inspection equipment, equipped with our proprietary AI image recognition system, accurately detects soldering defects that are invisible to the human eye. From solder paste printing to reflow soldering, from X-ray inspection to functional testing, our 12-step quality control process ensures a consistent product yield of over 99.6%. This technological expertise gives us the confidence to say: Choosing Fanway's PCB board assembly means choosing to align with the world's top manufacturing standards.

Market recognition speaks volumes. Today, Fanway's PCB board assembly products are used by leading domestic companies in the industrial control, medical device, and new energy vehicle sectors, and are also exported to Europe, America, Southeast Asia, and the Middle East, serving over 200 customers, including three of the world's top 20 electronics manufacturing service providers (EMS). Behind this achievement lies the long-standing trust of new and existing customers. They choose Fanway not only because we provide high-reliability products that meet IPC-A-610 Class III standards, but also because through process optimization (such as reducing multilayer board assembly cycles from 7 to 5 days) and supply chain collaboration (establishing a safe inventory pool for core materials), we have reduced overall product costs by 8%-12% compared to the industry average, truly achieving "quality at an affordable price."

"Once chosen, always trusted"—this isn't just a slogan; it's a commitment Fanway delivers on. We create a dedicated service profile for each customer, providing everything from DFM (Design for Manufacturability) analysis during prototyping to on-site quality control support during mass production, and a rapid after-sales response mechanism. This full lifecycle service elevates the partnership from a "transactional" to a "symbiotic" one. A European industrial robot company once faced an order default due to delivery delays from its original supplier. After urgently contacting Fanway, we quickly deployed a backup production line overnight, completed first-article verification within 72 hours, and delivered 1,000 PCBAs within 10 days. This not only helped the customer recover their losses but also led to a three-year strategic partnership.

Looking ahead, Fanway will continue to accelerate technological innovation and capacity upgrades: in 2024, we plan to introduce laser soldering equipment to enhance our high-precision module assembly capabilities; in 2025, we plan to build an intelligent, unmanned workshop to achieve digital control of the entire PCB board assembly process. We sincerely invite global sourcing partners to contact Fanway—whether for small-batch trial production or large-scale mass production orders. As your trusted PCB board assembly manufacturer and supplier, we firmly believe that a good partnership begins with a single choice and is built on long-term win-win outcomes.

Choosing Fanway for PCB board assembly means choosing a reliable manufacturing commitment—Once Selected, Ideal Forever.

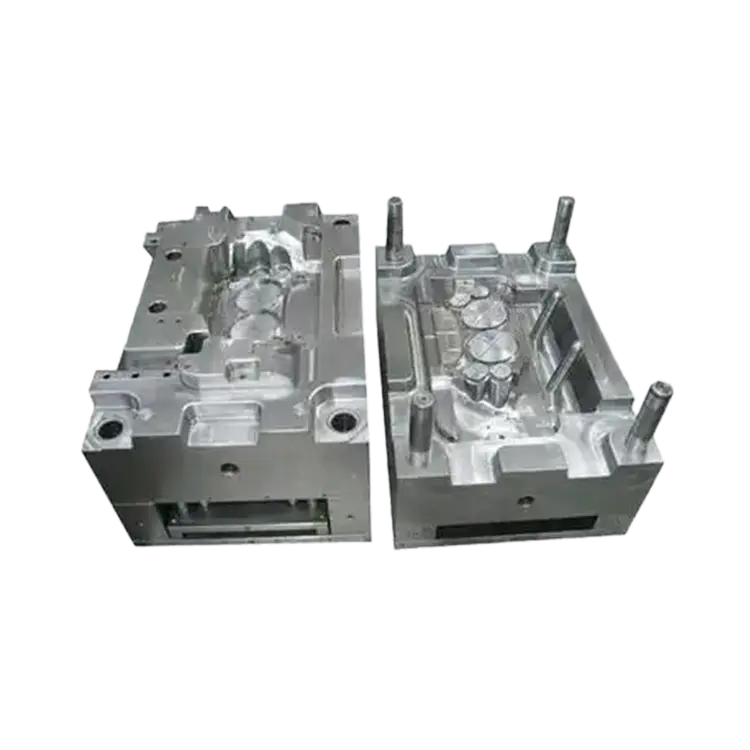

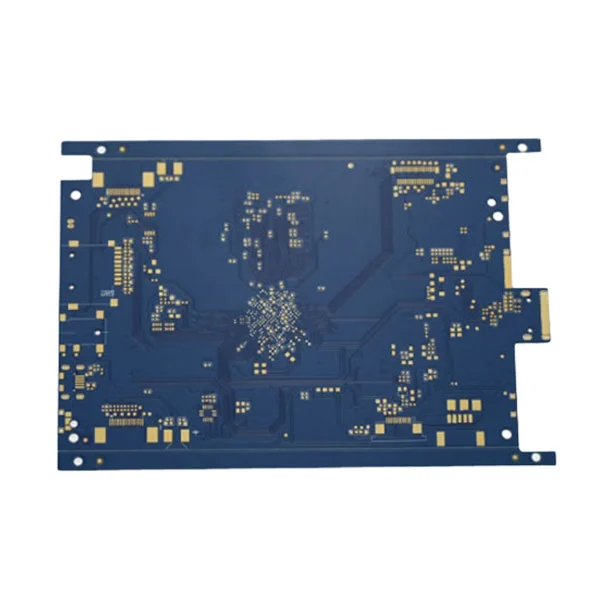

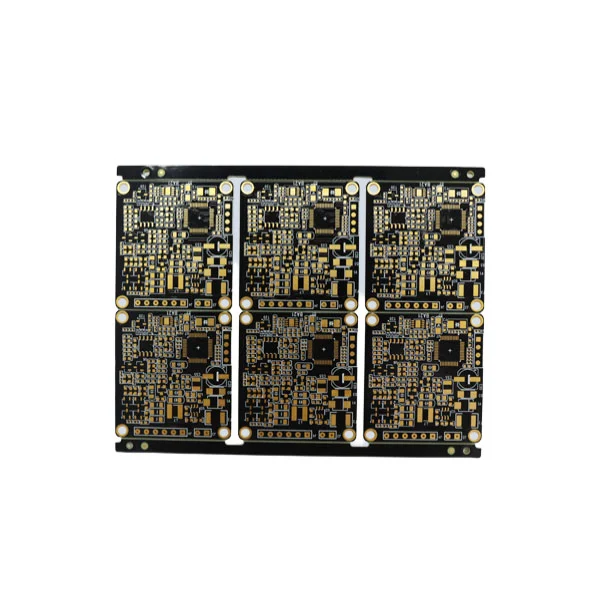

PCB Manufacturing and Assembly

Our purpose would be to give good quality items at competitive rates, and top-notch service to consumers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for PCB Manufacturing and Assembly, Never-ending improvement and striving for 0% deficiency are our two main quality policies. Should you need anything, never hesitate to get in touch with us.

PCB Manufacturing and Assembly, Now, with the development of internet, and the trend of internationalization, we've got decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.